ChBE 4900W

Chemical Engineering Lab II

FUNDAMENTALS

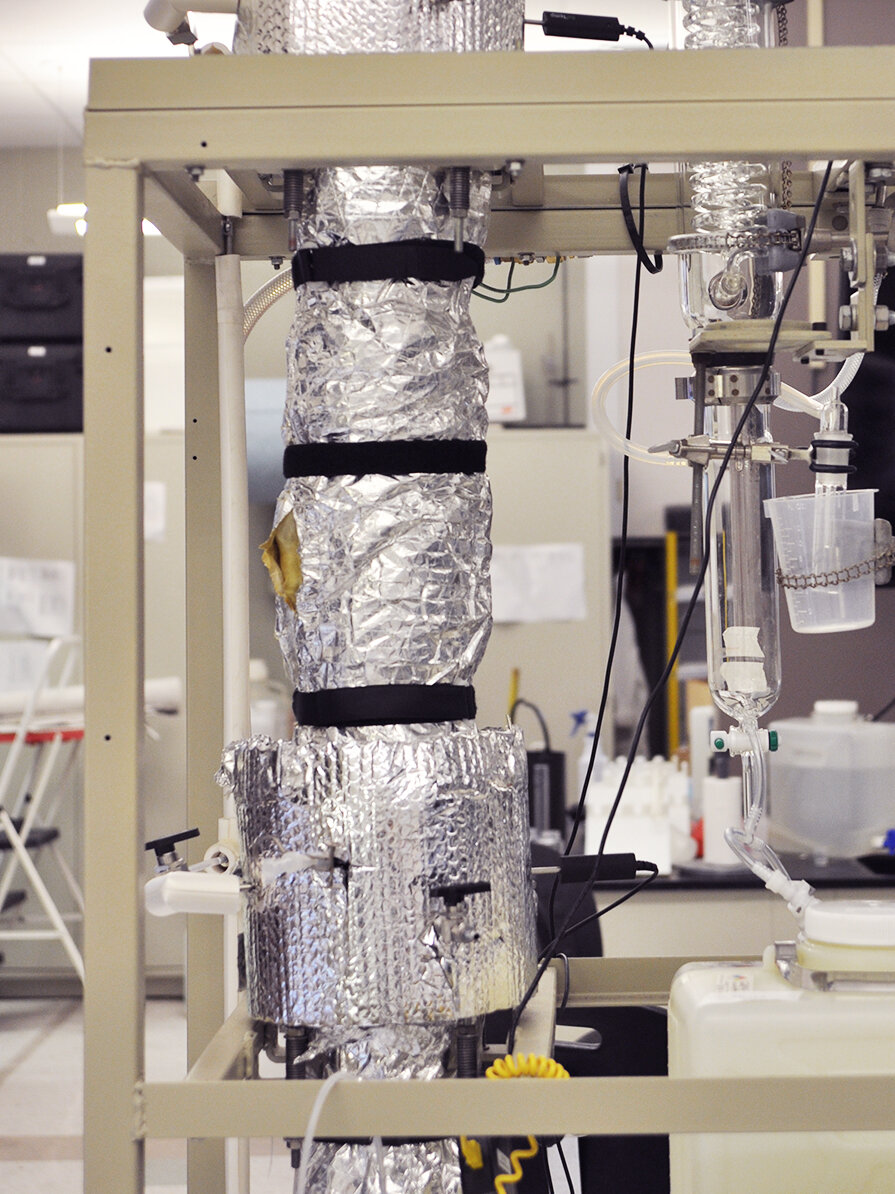

Distillation Columns

Reverse Osmosis

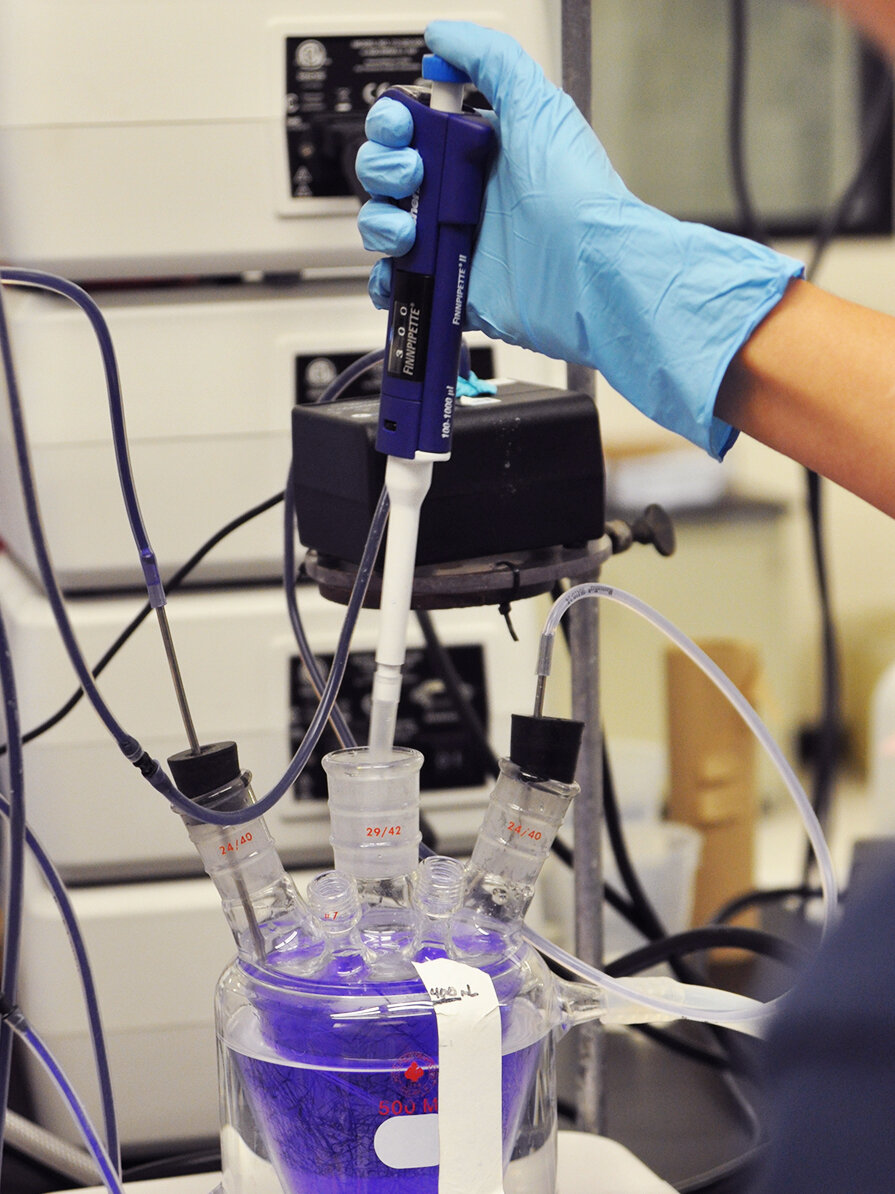

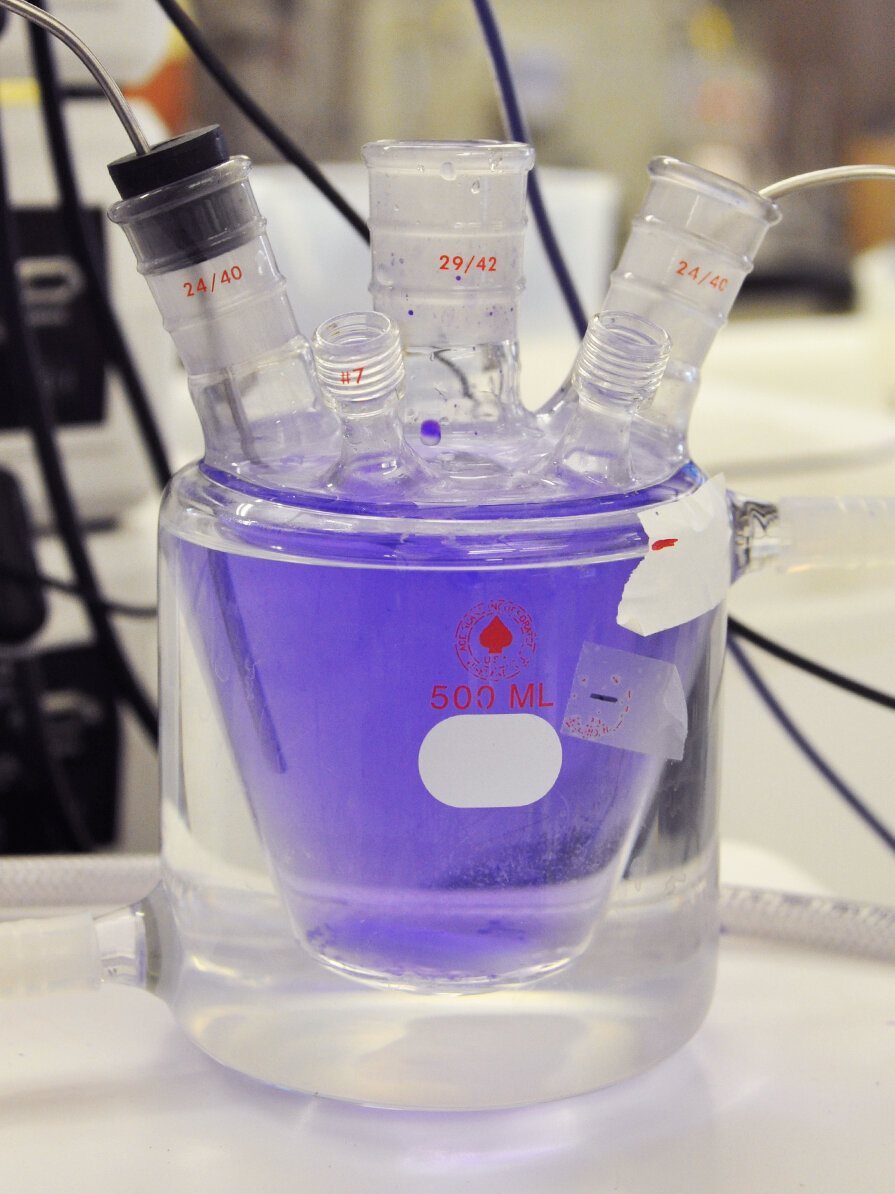

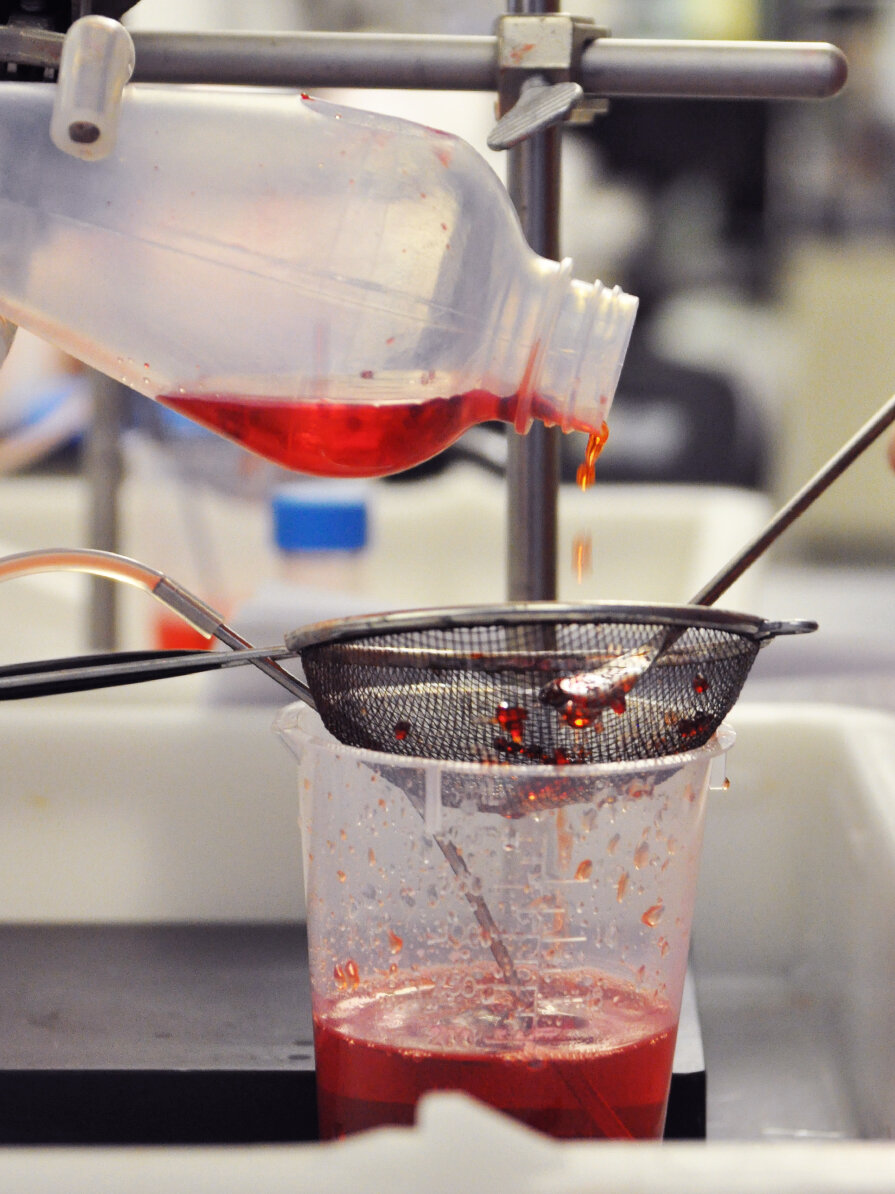

Chemical Reactors

EMERGING TECHNOLOGY

Pharmaceutical Drug Design and Delivery

UNIQUE EXPERIENCE

Application of Hazard Analysis Techniques

Distillation Scale-up Design

Reverse Osmosis Scale-up Design

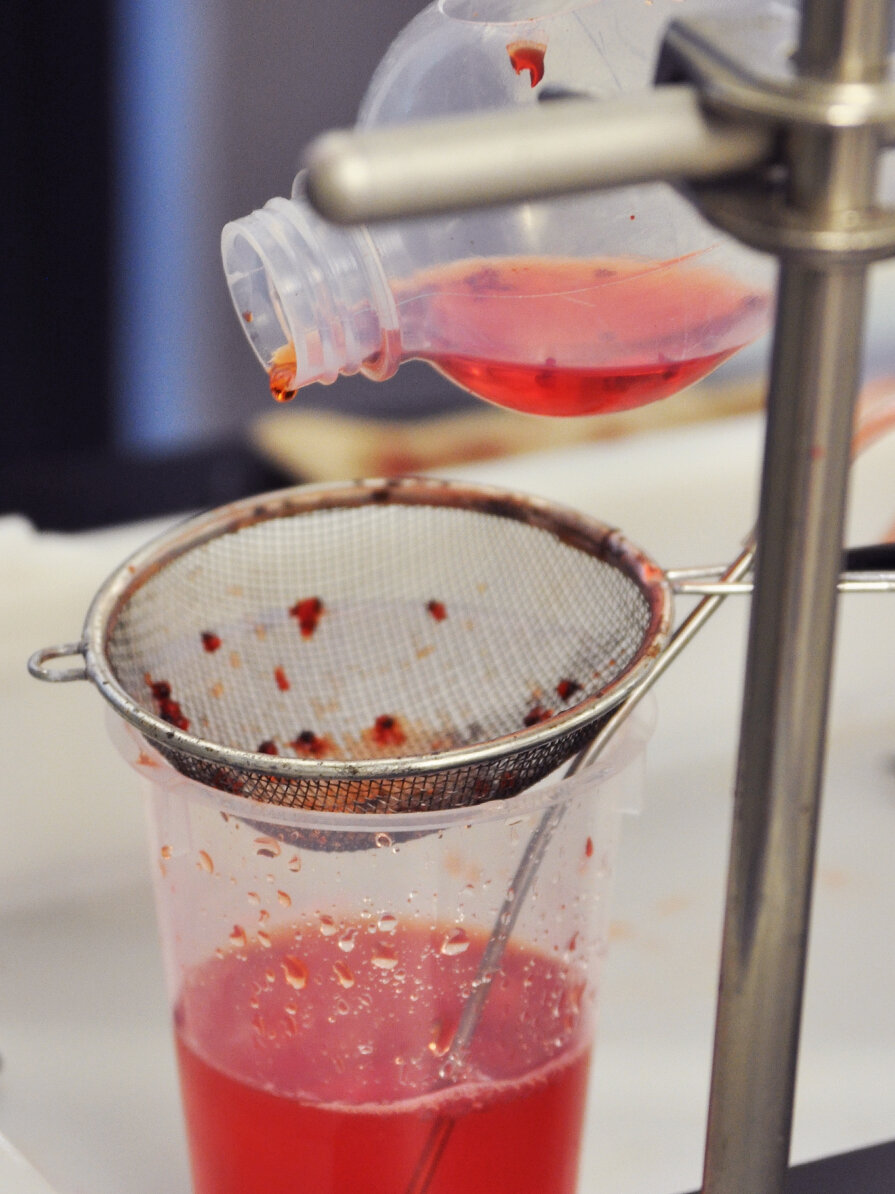

The ChIL is a laboratory facility with updated and custom-designed chemical engineering lab modules. In Lab II, lab-scale chemical process equipment was developed for the students to study different unit operations.

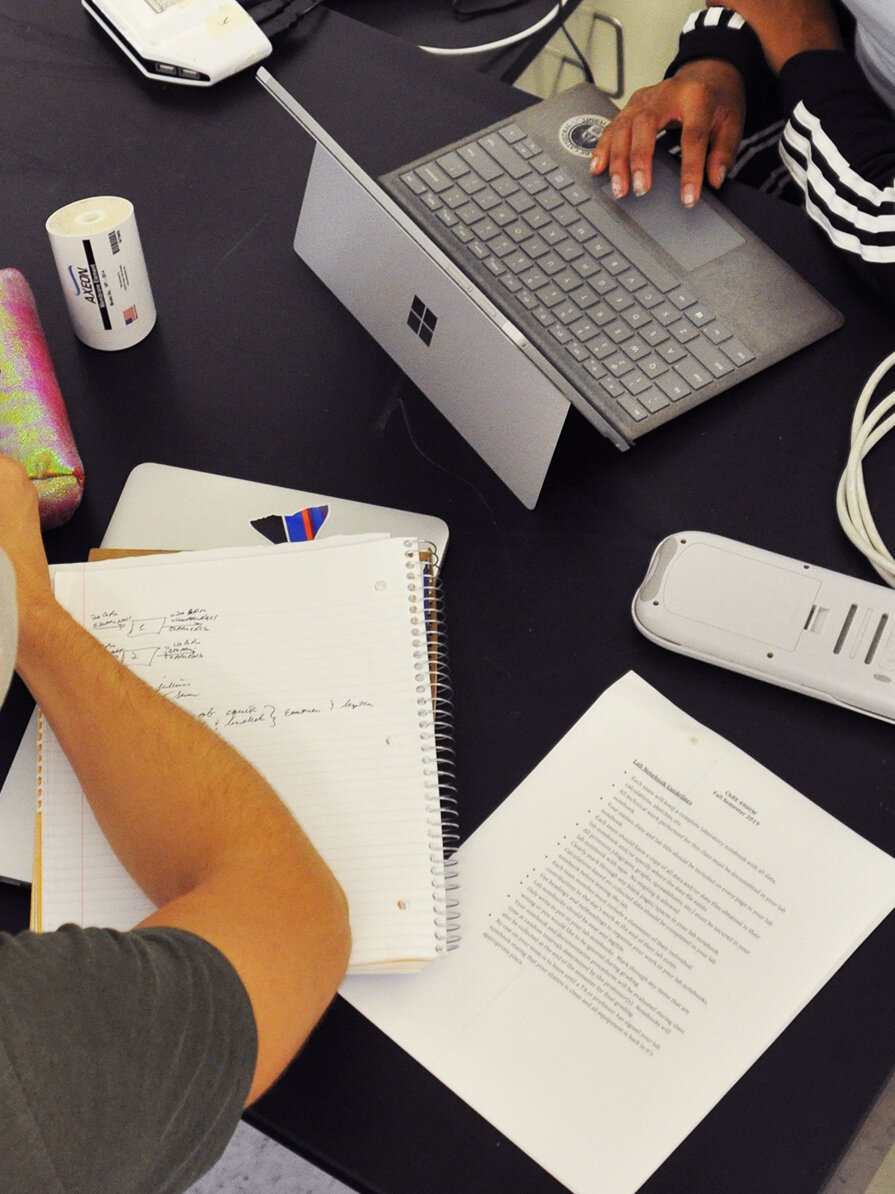

Two of the lab modules, Distillation and Reverse Osmosis, are two-week modules with the third week devoted to completing a computer-based Scale-up Industrial Design using data obtained from the lab-scale distillation and reverse osmosis units.

Distillation Scale-up Design:

Students learn a key skillset for chemical engineers: commercializing lab-scale experiments into profitable business ventures.

Evaluate column properties such as distillate concentration in the lab by adjusting feed location and reflux ratio.

Combine lab data with a specified production rate to create a column model in ASPEN.

Complete equipment and energy costing, along with heat exchanger design, using Vanderbilt’s custom HENOS Software.

Reverse Osmosis Scale-up Design:

Students learn another critical skillset for chemical engineers: designing environmental solutions for the problems of tomorrow.

Evaluate reverse osmosis performance such as rejection rate.

Complete a wastewater recycle network industrial scale-up task using Vanderbilt’s in-house WADE Software.

Compare unit costs in manufacturer’s vendor cost data sheet to meet the specifications of the task.